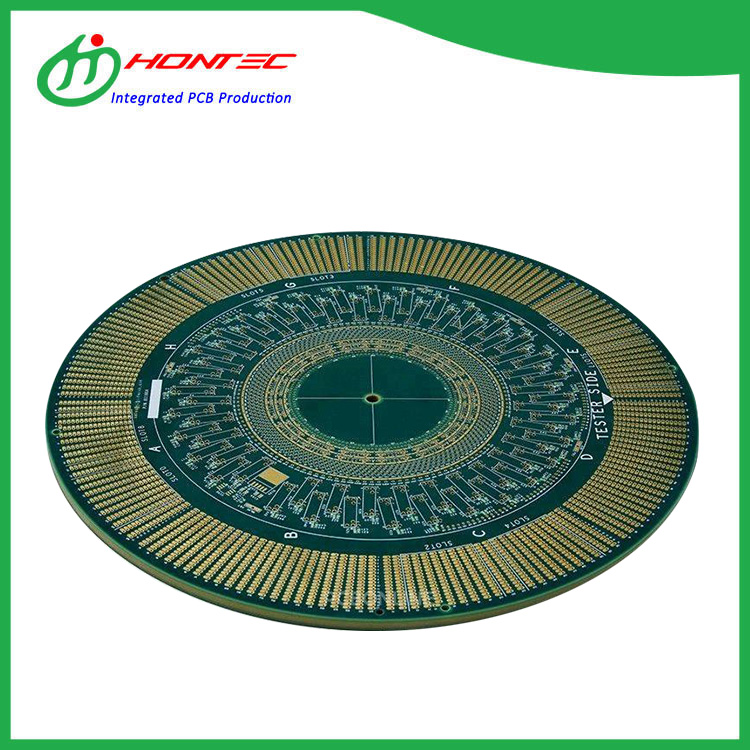

Multilayer PCB circuit board--The manufacturing method of multilayer board is generally made by the inner layer pattern first, and then the single or double-sided substrate is made by printing and etching method, which is included in the designated interlayer, and then heated, pressurized and bonded. As for the subsequent drilling, it is the same as the plating through-hole method of double-sided plate. It was invented in 1961.

Quick Details of Multilayer PCB circuit board

Place of Origin: Guangdong, China

Brand Name: Multilayer circuit board Model Number: Rigid-PCB

Base Material: ShengYi S1000-2M

Copper Thickness: 1oz Board Thickness: 3.0mm

Min. Hole Size: 0.1mm Min. Line Width: 3.5mil Min. Line Spacing: 3.5mil

Surface Finishing: ENIG

Number of layers: 26L PCB Standard: IPC-A-600

Solder Mask: Green

Legend: White

Product quotation: Within 2 Hours

Service: 24Hours technical services Sample delivery: Within 14 days

HONTEC Quick Electronics Limited (HONTEC), established in 2009, is one of leading quickturn Printed Circuit Board manufacturer, who specializes in high-mix, low volume and quickturn prototype PCB for high-tech industries in 28 countries. Upon efficiently quick around operation, PCB products contain 4 to 48 layers, HDI, Heavy Copper, Rigid-Flex, high frequency microwave,and Embedded Capacitance, and provides "PCB One-stop Shop" service to meet customers’ diverse demands. HONTEC is capable of producing 4,500 varieties monthly to meet 24-hour delivery for 4 layers PCB, 48-hour for 6 layers and 72-hour for 8 or more high-layer PCB at the fastest. Located in SiHui of GuangDong,HONTEC partners up with UPS, DHL and world-class forwarders to provide efficient shipping services.